Sleeper hewing

The overwhelming majority, if not all of the railway sleepers that came out of the Rushworth forest were hand hewn, which begs the question, why were they not just cut to specifications in the local sawmills? In states other than Victoria, many sleepers were cut by sawmills.

In Victoria the Commissioners of the Victorian Railways held a strong view that hewn sleepers were more durable than sawn ones.1 The average life of a railway sleeper was 20-30 years. The longer they lasted the better, because replacement costs were substantial.

Victorian Railways did not directly employ sleeper cutters. The men in the forest worked on contract at a set rate per sleeper, so the better you were, the more money you could make. Inspectors were employed to check the finished sleepers. Imagine the possibility of having some of your sleepers knocked back by an over-officious inspector after all the hours of work that had gone into their production. This is what happened at the Rushworth station in 1895, much to the chagrin of the local workers.2 Sometimes this would prompt workers to take their sleepers to another place where the inspector was not so pedantic.

Returns

Many of the sleeper hewers worked alone or with a mate in the forest. Obviously, it was tough physical work and the returns were not great. In 1930, the average earnings were four shillings and threepence per sleeper.3 That’s 43 cents each, or a bit over $20, allowing for inflation over the last 100 years.

At the time, it was suggested in one source that a skilled sleeper cutter’s average output was about 25 sleepers a week, which would earn them 5 pounds 6 shillings and threepence ($10.63/week or a bit over $500/week in today’s money). Not much when you consider that the workers had to walk or supply their own transport (horse or pushbike) out to their site where they would often camp for the week, as well as supplying the equipment needed to do their work and paying royalties and cartage contractors.

Tom Hall, who worked all his life in the timber industry around Heathcote, reckoned that proficient sleeper cutters could average six to eight sleepers a day, so the return might have been slightly better than that mentioned above.

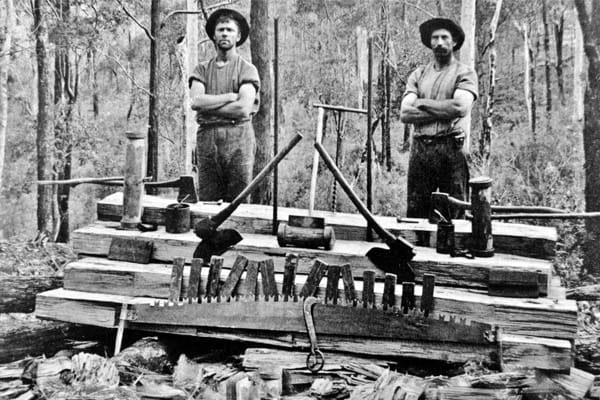

Tools of the trade

A sleeper hewer’s tools consisted of “a chopping axe, broadaxe, sledge hammer, wedges, crosscut saw, sleeper hook, cant hook and bar, a 10” x 5” (25.4 X 12.7 cm) board, chalk line, blue pot and branding hammer.”4 After a suitable tree was cut down with the chopping axe, it was then cut into nine foot billets (nearly 3m – the size prescribed by the railways) using the crosscut saw.

The sleeper was roughly shaped into the required dimensions, using the sledge hammer (or wooden maul before about 1910) and wedges. The 10” x 5” board was then used in conjunction with the string line to mark the billet. After scoring the billet with the ordinary axe, the broadaxe would be used to square off the excess wood. To ensure that the billet was off the ground while this was being done, the sleeper hewer would sit the unfinished sleeper up on two wooden skids. The sleeper hook, cant hook and bar were used to move the sleeper into the desired positions.

Transport

Once the sleepers were completed, they had to be transported to the Rushworth railway station. The carting was usually done by contractors using horse and dray. Around 1930 the cartage rate was ninepence (9c) per sleeper and the royalty paid to the Forest Commission about the same. Add to that the 4/3 (43c) received by the cutter and the price of a sleeper loaded onto railway trucks was about 6/- (60c).5

According to Tom Hall, about 10-12 sleepers would weigh a ton, so when a dray was loaded with about fifteen sleepers to take into town, the horse “was well laden and very busy!”6

At the southern (Heathcote) end of the forest, extensive tramways were eventually built to transport timber products to Tooborac and Heathcote stations, but this never happened on the Rushworth end of the forest.

References: 1 Brett, Dr Andre, post on the Economic History Society of Aust and NZ website on 28/11/2019; 2 Nagambie Times 21/6/1895; 3 The Argus 28/5/1930 p 10; 4 Hand Tool Preservation Association of Australia newsletter, October 1989, p 9; 5 Hall, Tom, The Life of the Timber Industry in the Shire of McIvor and Heathcote (1985 notes); 6 ibid p 7